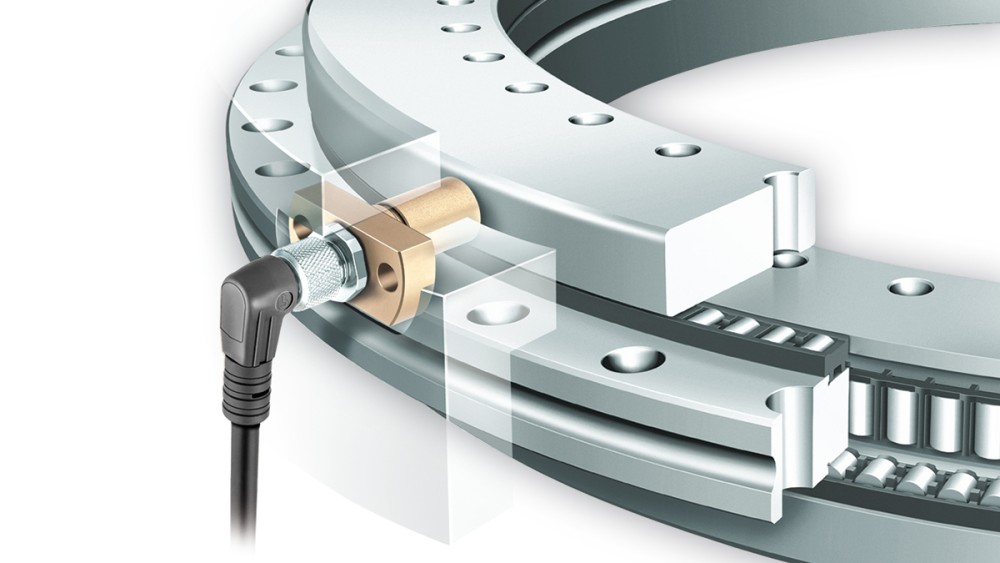

YRTCM/YRTSM measuring system bearings

Measuring system bearings with SRM measuring electronics for incremental, magneto-resistive angular measurement

Extremely high machining quality and increased machine availability for electrically driven axes in machine tools

Your benefit:

- Excellent positioning accuracy and high machining quality

- High machine availability

- Extremely short initial operation times

- Lower installation space requirements

- Free space in the center of the machine

Comprehensive reasons to use YRTCM/YRTSM measuring system bearings

YRTCM/YRTSM measuring system bearings allow precise, reliable angular measurement to be carried out directly in the machine axis, which produces extremely high machining quality and high machine availability.

The SRM angular measuring technology employs a common, proven electronic interface (analogous to 1 Vss), which makes the angular measuring system electronically compatible with all machine tool control systems.

As a result of the reliable and fail-safe magneto-resistive operating principle, machine failures are prevented and outstanding levels of machine availability achieved.

The required installation space is reduced, which increases the size of the available machining area. What is more, the free space in the center of the axis is available for power cables, data cables, and media supply lines.

Features

- Incremental angular position values with distance-coded reference marks

- Magnetic operating principle

- Integrated into the bearing

- Hollow shaft and free space in the center of the axis

- Electronic interfaces (analogous to 1 Vss)

- Electronically compatible with all conventional machine tool control systems

- Precise angular measurement and maximum positioning accuracy

- Extremely high levels of control rigidity thanks to an angular measuring system integrated directly into the axis

- High reliability

- Functionally unsafe, must not be used for safety relevant axes